Pu Foam & Foil Insulation Properties | |||

|---|---|---|---|

Items | Specifications (+/-) | ||

Thickness of Pu Foam | 20mm | ||

Type of Insulation | Bonded Rigid Polyurethane | ||

Insulation Density of Pu Foam | 36-40kg/m3 | ||

Insulation Grade | CFC Free | ||

K value ( Thermal Conductivity) | 0.022w/mK | ||

R value ( Thermal Resistance) | 1.06m2K/W | ||

Product Specifications | |||

|---|---|---|---|

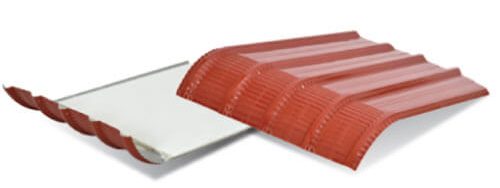

Profile | SENGDEK®SuperRib Pu Foam & Foil | ||

Effective Width | 762mm | ||

Depth of Rib | 25mm | ||

Yield strength (MPa) | G300/G550 | ||

Minimum Roof Pitch | 3° without end lap | ||

Tolerance | Length ± 5mm, Width ±5mm Thickness of foam ±3mm | ||

Thickness Available Chart | |||||||

|---|---|---|---|---|---|---|---|

Base Metal Thickness(mm) | 0.23 | 0.25 | 0.28 | 0.30 | 0.35 | 0.40 | 0.48 |

Total Coated Thickness(mm) | 0.28 | 0.30 | 0.33 | 0.35 | 0.40 | 0.47 | 0.53 |

Weight(kg/m2) | 2.31 | 2.46 | 2.82 | 2.93 | 3.46 | 4.20 | 4.76 |

Min. Yield Strength(MPa) | G300/ G550 | G300/ G550 | G300/ G550 | G300/ G550 | G300/ G550 | G300/ G550 | G300/ G550 |

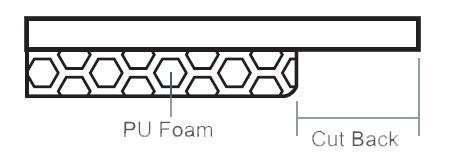

Panel End Cut Back | Panel End Lap |

|---|---|

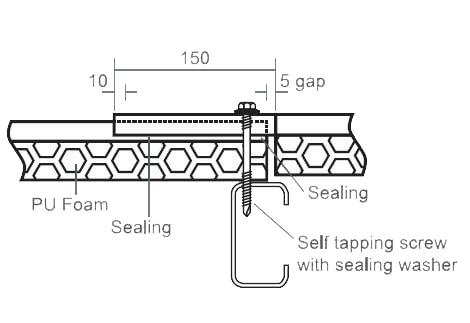

For Installation of insulated metal roof, the following measures are recommended

|  |

Closed Cell (Rigid) VS Opened Cell (Semi Rigid) Polyurethance Foam | |

|---|---|

Closed Cell | Opened Cell |

Heat and sound insulator

| Heat and sound insulator

|

Compressive Strength

| Compressive Strength

|

Water absorption

| Water absorption

|

Lifespan

| Lifespan

|